Pro-Hydraulics has fully comprehensive repair facilities, in Johannesburg and Durban, being 2800 square meters and 2000 square meters respectively, or by a facility authorized by ourselves, elsewhere, in Southern Africa.

We repair hydraulic pumps, motors, valves, cylinders, systems and associated electronics, to original equipment specifications and standards, all in line with our ISO 9001:2015 accreditation.

With a staff complement of 78 personel, all our available technical information, machinery and special tools, we are able to carry out repairs to all products, listed under our “ Products” section, drawing the spare parts from our well stocked warehouse in Johannesburg, and stores in Durban.

We do however, do repairs to all major brands of hydraulic components, and carry the spares for these accordingly.

Assessment: On receiving the component for repair and documentation, it is stripped, cleaned and inspected. The inspection report, will list what spare parts need to be replaced or re-furbished.

A formal quotation and or a report is forwarded to the customer for approval. Prior to commencement of repair, the customer may inspect, the damaged goods at our works, or discuss the possible cause of failure. The unit is stored in a clean environment, awaiting official go-ahead for repair.

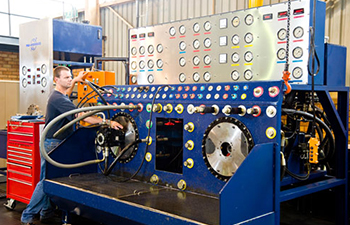

Repair: A qualified Technician, utilises the latest equipment and technical information, for the correct assembly procedure for the component.

Any re-furbished parts, or in-house manufactured parts, take place in one of our machine shops, with parts being manufactured to original equipment specifications.

Testing: All repaired units are tested, to new equipment standards, on one of our eight test rigs, or simulators.

Final settings to customer requirements, prior to painting and packing.We are available to advise customers, on maintenance on their systems and how to avoid failures.